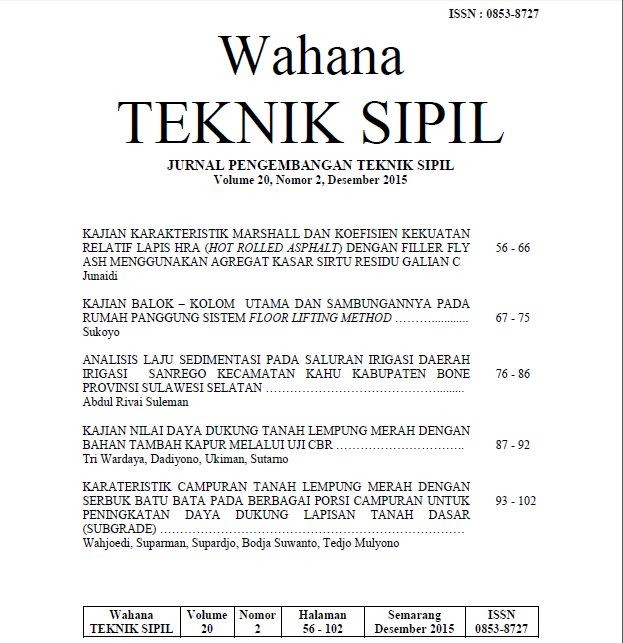

Kajian Karakteristik Marshall Dan Koefisien Kekuatan Relatif Lapis Hra (Hot Rolled Asphalt) Dengan Filler Fly Ash Menggunakan Agregat Kasar Sirtu Residu Galian C

DOI:

https://doi.org/10.32497/wahanats.v20i2.144Keywords:

fly ash, gravel excavation C, HRA, Marshall test, rural roadsAbstract

Environmental problems such as pollution, destruction and disasters over the years is still ongoing and increasingly widespread. The condition not only causes environmental degradation but also a very serious impact on health and the human soul. Damage to the environment due to the soil / land also occurred in Waterford District C in the form of mineral mining (gravel). Mining is long overdue and is expanding. The existence of the mine excavation C has caused another problem in the form of accumulated waste material in gravel scattered around the place and the mining area. Starting from the above, it is necessary to think about how to take advantage of the rest of the mine rock gravel on aspalisasi activities. Step that needs to be done is to study the quality and characteristics of the asphalt mix by stacking materials using the gravel with reference to the specifications and requirements specified. This paper presents the results of research into the use of coarse aggregate gravel quarry C residue and fly ash filler in asphalt Hot Rolled Asphalt (HRA) in terms of the relative strength coefficients (a1) material in order to know the needs of pavement thickness HRA in the field.

Coarse aggregate materials used in the study came from the residual quarry village C Munggangsari / Purbosari excl. Ngadirejo kab. Waterford, fly ash material derived from PT Jati Kencana Concrete (Ungaran) and AC 60/70 bitumen production Pertamina Cilacap. Equipment used for the study is the means test in the asphalt mixture Materials Laboratory of Civil Engineering Department Semarang State Polytechnic. Number of test specimens to be used in this study is 30 pieces and the test is done with reference to the SNI 06-2489-1990, including the value of stability, flow and MQ, density analysis and voids (VMA, VFWA, VITM). The study results showed that the residual gravel excavation C can be used as a mixture in which the HRA asphalt mix asphalt with gravel aggregate quarrying C has a value of stability between the above 744, the value of a1 between 0.28 to 0.38 which means it can support the traffic with heavy density. Based on the results of plotting the data parameters to the requirements of Highways marshall, obtained the optimum bitumen content of 7%. While based on a mixture of the three variations of rock and ash content of different fly ash show that the levels of HRA mixture with 100% filler stone dust showed the highest value a1. This shows that the addition of aditive fly ash as filler in the mix HRA HRA instead lowered pavement performance.

Downloads

Published

Issue

Section

License

Authors who publish with this journal agree to the following terms:Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).