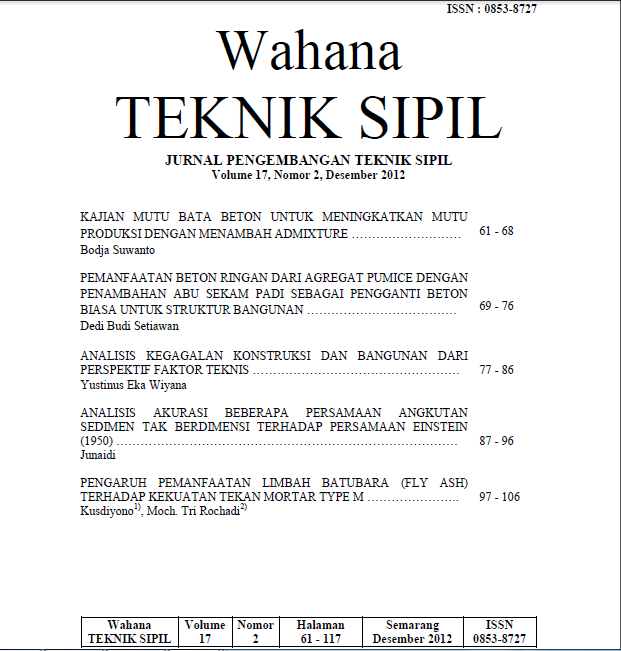

Pengaruh Pemanfaatan Limbah Batubara (Fly Ash) Terhadap Kekuatan Tekan Mortar Type M

DOI:

https://doi.org/10.32497/wahanats.v17i2.119Keywords:

fly ash, compressive strength, mortar type MAbstract

Fly ash and bottom ash is a solid waste generated from coal burning power plants. Solid waste is present in large enough quantities. The amount is quite large, so it requires a management that does not cause environmental problems such as air pollution, water and ecosystem degradation. The research done in the field of Engineering Materials Research in an effort to utilize industrial waste that can be used for mortar to other industrial materials, and the results of the study are intended to address the increasingly complex problems of the solid wastes such as fly ash and how to maximize its utilization. One way to capitalize is made mortar. To determine the extent of the effect of adding fly ash on compressive strength of mortar, the addition of the composition is mixed with fly ash ranging from 0%, 5%, 10%, 15% and 20% of the weight of cement with water factor cement is determined the same in all variations of the mixture. The samples used were cuboid (5 cm x 5 cm x 5 cm), planned mortar is Type M. The samples were tested at ages 7, 14, 21 and 28 days, with the first treated before testing. Total sample of 60 fruit, consists of five variations and each variation of a total of 12 pieces. The results obtained increased compressive strength highest average in the addition of Fly Ash every 5% of the well at a young age (7 to 28) days with the highest compressive strength 7 days reached 373.71 kg / cm ² at 20% addition of Fly Ash and 403, 41 kg / cm ² for the addition of 15%, the compressive strength was the lowest average age of 14 days obtained at 307.68 kg / cm ² at 5% addition of Fly Ash and 28 days amounted to 355.78 kg / cm ² to mix mortar with the addition of Fly Ash of 10%. With the regression equation Y = 8.244 X ² - 40.47 x + 384.3 and the correlation R ² = 0.987. This is because Fly Ash has a fine grain that will make the mortar more slashy (workable), solid and makes cavities between aggregate grains filled by Fly Ash, so that the pores and cavities become smaller, thereby increasing the compressive strength of mortar. Thus the picture of the use of Fly Ash as a mortar significantly proven.

Downloads

Published

Issue

Section

License

Authors who publish with this journal agree to the following terms:Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).